One of the most fundamental things that I feel is commonly missed in online sewing content is teaching textile basics. It may seem silly but understanding the structure of your fabric is essential so you understand what fabric is good for what sewing project. There is a wide range of things to learn and understand about fabric and I am learning new things everyday but in this blog I just wanted to touch on the basics that I feel every sewist should know.

We tackle these ideas in our adult level 1 sewing course as a foundational idea on how to sew clothes. If you are interested in a more well rounded understanding of why these textile basics matter you can join one of our weekly classes!

First things first – There are generally two different types of fabric structures.

Woven vs. Knit

Wovens are made on big looms. In the most basic form it is a lot of long fibers running horizontal and vertical that alternatingly overlap to make a strong cloth. wovens are ideal for garments that require more structure and most often you would need some form of a closure to make this garment. Button up shirts, most outerwear like coats, denim jeans, and suits are all made from wovens.

Knits are made on knitting machines and involve loops that interlock to create a stretchy cloth. Knits are ideal for garments that require a lot of forgiveness in movement, tshirts, leggings, sweatpants, and hoodies are all made from knits.

Now, not all knits are super stretchy and not all wovens lack stretch, but in general it is best to assume a woven won’t have much stretch and knits will have more.

The second thing to know after this is general cutting protocol

All Woven fabrics have these general things to remember when cutting out (fair warning this is vocab heavy)

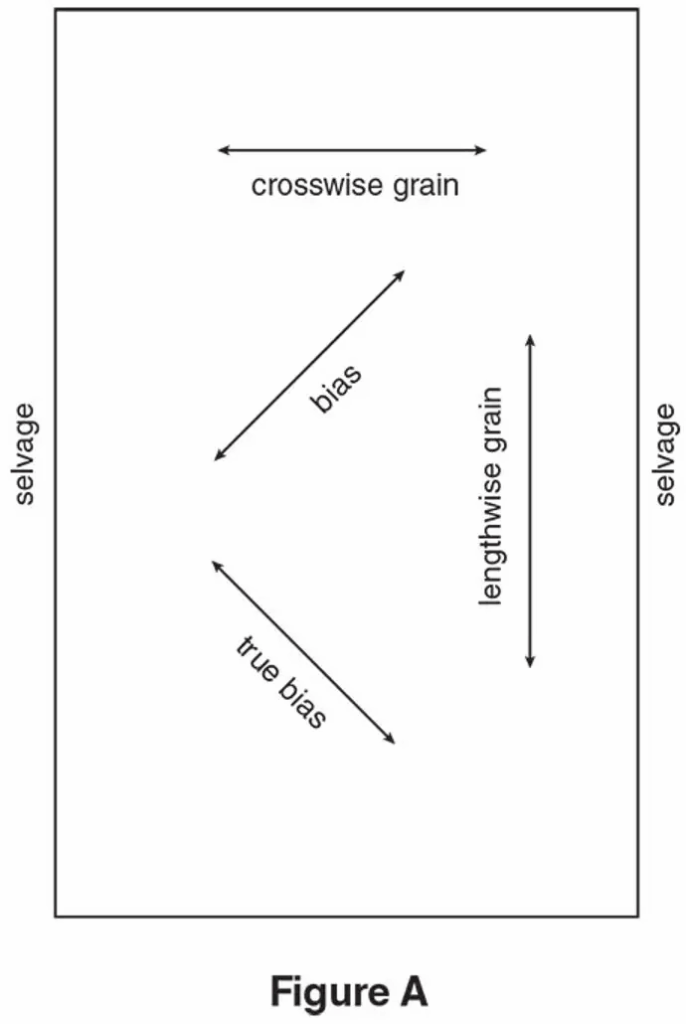

Warp: Warp is the longest fibers running through a cloth, these are the vertical lines running through a woven that are generally the strongest and not stretchy at all.

Weft: Weft is the horizontal lines that run through a woven, these generally have a little bit of “stretch” or give in them.

Selvedge: The Selvedge is the manufactured finished edge of the cloth. Commonly this edge will have a different colour and be denser in weave. The Selvedge is parallel to the warp fibers.

Grainline: On every sewing pattern there will be a line with arrows on the end called a grainline, this grainline is letting you know that your warp fibers should be running in the same direction. It is important to cut your garment on grain so you ensure the stretchiest fibers run around your body properly and that the garment fit and drape is accurate to the pattern. The grainline is parallel to the Selvedge.

Bias: the Bias is the 45 degree angle of the cloth, things cut on the bias will have the most stretch that a woven cloth can have. If you have ever had a sleeve or pant leg that always twists around your body it’s because the manufacturer accidentally cut your garment on the bias. The bias can also be used to create beautiful draped and fitted skirts and dresses.

For knits, the core concept of the grainline and bias can be applied with some exceptions. It is always important to double check on your knit which direction has the most stretch and ensure that the most stretch will go around your body or be parallel to the horizon.

After you come to understand these core concepts of choosing the proper cloth and cutting out your garment properly then you can build on your fiber knowledge and learn what fabric works with what garment. I have written tons of blog posts about the fabrics we store at the studio and what they will work the best for!